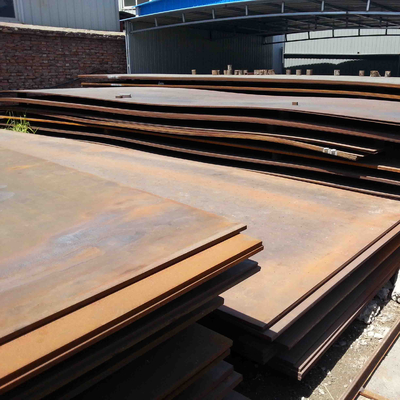

AR360 Ar400 Ar500 Nm400 Wear Resistant Steel Plate Hot Rolled Hardened Steel Sheet

Product Details:

| Place of Origin: | China |

| Brand Name: | TISCO |

| Certification: | ISO CE |

| Model Number: | NMB-005 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 ton |

|---|---|

| Price: | Elaborate |

| Packaging Details: | wooden box |

| Delivery Time: | 5-25days |

| Payment Terms: | L/C, D/A, D/P, T/T |

|

Detail Information |

|||

| Name: | Wearing Steel Plate | Material: | Steel |

|---|---|---|---|

| Standard:: | AiSi, ASTM, Bs, DIN, GB, JIS | Length:: | As Requirement |

| Technology: | Hot Rlloed | Advantage:: | Accurate Dimension |

| Special Use:: | Wear Resistant Steel | Width:: | 0.3m-3m |

| Highlight: | nm400 wear resistant steel plate,Ar500 wear resistant steel plate,AR360 Hot Rolled Hardened Steel Sheet |

||

Product Description

Hot Rolled Wear Steel Ar400 Ar500 Nm400 Nm500 Wearing Steel Plate

This quality is quantified by a Brinell hardness number (BHN) which ranges from roughly 26 – 600 Brinell. Abrasion resistant steel grades usually show hardness values of up to 500 Brinell with intermediate carbon contents of up to 0.30%.

Hardened steel is resistant to wear, rough usage, high-impact pressure and shock. It is used to make power shovels, steel balls, nozzles, surgical instruments, crushers and plates for rock-processing.

|

Product Name

|

hot rolled wear steel ar400 ar500 nm400 nm500 wearing resistant steel plate

|

||

|

Standard

|

AISI,ASTM, EN, BS, GB, DIN, JIS

|

||

|

Materials

|

NM360,NM360L,NM400,NM400L,NM400A,NM450,NM450L,NM450A,NM500A

DILLIDUR400,DILLIDUR500,DILLIDUR400V,DILLIDUR500V,DILLIDUR450V

QUARD400,QUARD450,QUARD500 FORA400,FORA500,CREUSABRO4800,CREUSABRO8000

RAEX400,RAEX450,RAEX500 |

||

|

Inspection

|

ISO,BV,SGS,MTC

|

||

|

Packing

|

Waterproof paper, and steel strip packed.

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

||

|

Supply Ability

|

250000 metric tons/Year

|

||

|

MOQ

|

5 metric ton,sample order accepted

|

||

|

Shipment time

|

Within 7-10 workdays after receiving deposit or L/C

|

||

|

Chemical Content

|

||||||||

|

Steel/Grade

|

C

|

Si

|

Mn

|

P

|

S

|

AL

|

Cr+Ni+Mo

|

Nb+V+Ti

|

|

NM360/AR360

|

0.10-0.30

|

0.20-0.40

|

1.00-2.00

|

≤0.015

|

≤0.003

|

≥0.20

|

<0.6

|

|

|

NM400/AR400

|

0.10-0.40

|

0.20-0.40

|

1.00-2.00

|

≤0.015

|

≤0.003

|

≥0.20

|

<0.9

|

|

|

NM450/AR450

|

0.10-0.40

|

0.20-0.40

|

1.00-2.00

|

≤0.015

|

≤0.003

|

≥0.20

|

<1.2

|

|

|

NM500/AR500

|

0.10-0.40

|

0.20-0.45

|

1.00-2.00

|

≤0.015

|

≤0.003

|

≥0.20

|

<1.5

|

|

|

NM550/AR550

|

0.10-0.50

|

0.20-0.45

|

1.00-1.50

|

≤0.015

|

≤0.003

|

≥0.20

|

<2.0

|

|

|

NM600/AR600

|

0.10-0.50

|

0.20-0.45

|

1.00-1.50

|

≤0.015

|

≤0.003

|

≥0.20

|

<2.5

|

|

|

Mechanical property

|

||||

|

Grade

|

Tensile strength

|

Elongation

|

Hardness

|

-20℃ Impact energy

|

|

(Mpa)

|

(%)(min)

|

(HBW)

|

AKv/J (min)

|

|

|

NM360

|

≥1100

|

12

|

330-390

|

24

|

|

NM400

|

≥1200

|

10

|

370-430

|

24

|

|

NM450

|

≥1250

|

7

|

420-480

|

24

|

![]()

![]()

Application

![]()

Packing

![]()