400 450 500 550 600 Wear Resistant Steel Plate AR HB Steel Plate

Product Details:

| Place of Origin: | China |

| Brand Name: | TISCO |

| Certification: | ISO CE AISI ASTM |

| Model Number: | NMB-010 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 ton |

|---|---|

| Price: | Elaborate |

| Packaging Details: | Wooden pallets and container |

| Delivery Time: | 5-25days |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 2500 tons/week |

|

Detail Information |

|||

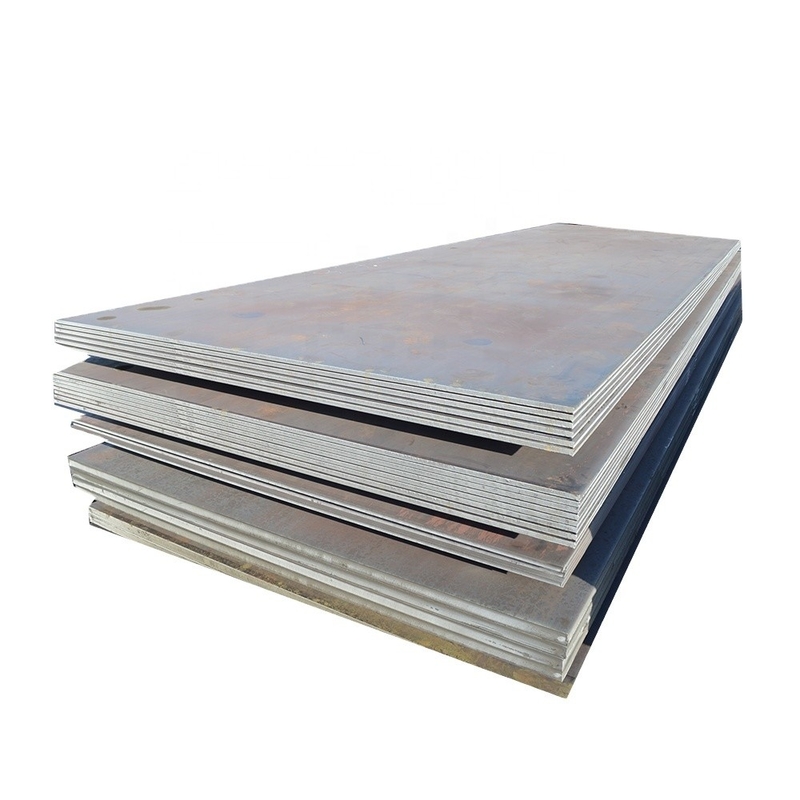

| Name: | Wear Resistant Steel | Material: | Carbon Steel |

|---|---|---|---|

| Thickness: | 6.0-200mm | Standard: | ASTM,AISI,JIS,GB, DIN,EN |

| Tolerance: | ±1% | Processing Service: | Welding, Punching, Cutting, Bending, Decoiling |

| Width: | 100-3000mm Or Customized, 100-3000mm Or Customized | Length: | 100-12000mm Or Customized, 100-12000mm Or Customized |

| Highlight: | 600 Wear Resistant Steel Plate,500 steel plate,400 steel plate |

||

Product Description

Hardness 400 450 500 550 600 Wear Resistant Steel Plate Sheets Price AR HB s

The surface hardness and the properties of the core are obtained by hardening and tempering. This process leads to a hard, wear-resistant surface layer, while the core is comparatively tough, which enables the steel to withstand impact stresses without fracture and lends it a high resistance to wear.

This material can withstand frequent abuse and heavy loads without damage or failure. It is also better able to resist rust and corrosion than standard steel products. Despite its many advantages, hardened steel may not be appropriate for all types of applications.

| No. | Grade | Feature and Property |

| 1 | General Wear Plate | C:3.0-4.5% Cr:15-27% |

| 2 | High Chromium Wear Plate | C:3.5-5.5% Cr:27-40% , wear resistant overlay thickness maximum up to 25mm. |

| 3 | Impact Resistant Wear Plate | Independent R&D, with high wear and high impact resistance. |

| 4 | Heat Resistant Wear Plate | Independent R&D , with heat resistance maximum up to 900 ℃. |

| 5 | No Crack Wear Plate | Rockwell Hardness:50-55HRC, mainly used in housing liner of steel mill, domestic unique product. |

| 6 | Special Chemical Elements Wear Plate | OEM customized, Chemical elements: Mo, Nb, Ni, W, V, etc. |

| Other Feature and Property | ||

|

Chemical composition: Wodon wear plates are manufactured by welding one or multiple abrasion resistant layers on a medium or low carbon steel base plate. The overlay alloy has a high amount of chromium carbide hard particles.

Microstructure: The carbide (Cr7C3) volum fraction on the microstructure is above 50%.

Rockwell Hardness: Chromium carbide hard particles are distributed evenly throughout the layer, creating a strong microstructure, The hardness is between HRC58-65 and depend on the overlay's thickness.

Wear resistance: Our test shows that the wear resistance of Wodon plate is 20 times higher than low carbon steel and 8 times than heat treated steel.

Flatness tolerance: Flatness tolerance is ±3mm/m

Thickness tolerance: Uniform overlay thickness, with tolerance within 0-0.5mm.

|

||

| The Main Thickness | ||

|

3+3,4+4,5+5 6+4,6+5,6+6,6+8 8+4,8+5,8+6,8+7,8+8 10+4,10+5,10+6,10+7,10+8,10+9,10+10,10+20 12+4,12+5,12+6,12+7,12+8,12+10,12+11,12+12,12+18,12+20 14+6,14+8,14+10 16+6,16+8,16+10 18+6,18+8,18+10 20+5,20+6,20+8,20+10,30+10,40+10,20+20,20+25

We can customize the plates in different sizes and thicknesses based on customer's drawings.

|

||

![]()

![]()

![]()

![]()

![]()